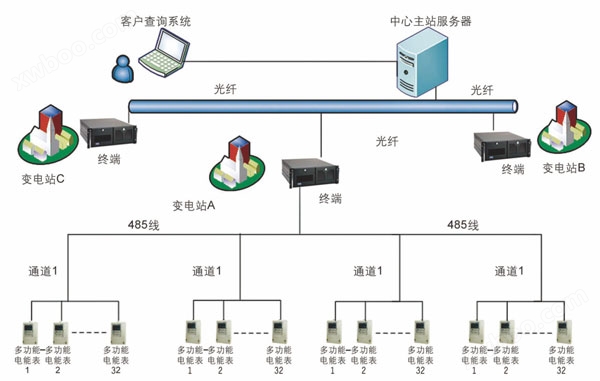

The substation energy remote terminal is a remote automatic meter reading terminal developed by Xinkai Pu. The terminal collection device uses RS485 bus to read the data from the on-site energy meter, and uploads the data to the server in the computing center through Ethernet interface using optical fiber (1Pover SDH, etc.). It adopts a hardware platform with I~ARM9 microprocessor as the core, as well as an embedded real-time software platform consisting of commercial real-time operating system (RTOS), embedded TCP/IP protocol stack, and embedded file system. This system fully considers the characteristics of a large number of meters and complex types of energy meters in substations. Embedded terminal acquisition devices can read multiple data types and support up to 128 energy meters, achieving automation in electricity management. They can be used in factories, stations, and other occasions.

Functional Features

1. The ARM9 microprocessor has high processing power and supports various storage media such as DataFlash, NaridFlashl, and SD card, with a large information storage capacity;

2. This system is built on the ARM9 hardware platform and an embedded real-time software platform consisting of a real-time operating system (RTOS), an embedded TCP/LP protocol stack, and an embedded file system. It has high trustworthiness, reliability, stability, good scalability, and secure and reliable information storage;

3. The default configuration of the data transmission channel adopts 10M/100M adaptive Ethernet, which has a large communication capacity and can transmit a large amount of data in real time. It fully utilizes the broadband fiber optic resources (such as IPoverSDH) widely laid in substations, and can achieve data transmission without relying on other communication operators, with no communication operation costs; In addition, this device can also expand other communication methods according to user needs, including GPRS/CDMA, PSTN, etc.

4. The system is based on a unique high-performance redundancy mechanism and algorithm, supporting dual machine redundancy operations and ensuring the reliability of both system operation and data storage.

| TECHNICAL INDEX | |

| project | Technical Parameter |

| Acquisition method | Real time collection, automatic timed collection, and automatic copying |

| Mean time between failures (MTBF) |

MTBF ≥ 80000 hours, annual availability ≥ 99.99% |

| Data storage capacity | 256MB (expandable) |

| power input | 220V, allowable deviation -20%~+20% |

| Power consumption | Less than 10 volt ampere per phase |

| Communication Channel | Collect RS-485 interfaces: 4; Local configuration RS232 communication interface: 1; RJ45 Ethernet interface: 1 |

| Usage environment | Normal operating temperature:- 25℃~+65℃; Extreme working temperature:- 40℃~+75℃ Relative humidity: 10%~100% (including condensation) Atmospheric pressure: 63~108kPa |

| Serial Number | project | terminal | |

| 1 | data acquisition | Energy meter data collection |

√ |

| 2 | Data management and storage | Real time and current data |

√ |

| Historical daily data |

√ |

||

| Historical monthly data |

√ |

||

| Key user collection |

√ |

||

| Monitoring the operation status of electric energy meters |

√ |

||

| 3 | Parameter settings and queries | Clock calling and timing |

√ |

| Terminal parameters |

√ |

||

| Meter reading parameters |

√ |

||

| Other |

√ |

||

| 4 | Event record | Important event records |

√ |

| General event records |

√ |

||

| 5 | data transmission | Connect with the main station via Ethernet interface Using optical fibers for communication |

√ |

| 6 | Local functionality | Operation status indication |

√ |

| Local maintenance interface |

√ |

||

| 7 | Terminal maintenance | Self check and self recovery |

√ |

| Terminal initialization |

√ |

||

| Remote software download |

√ |

Welcome to inquire about Xinkai Pu's products related to digital campus, campus one card, enterprise one card, city one card, public transportation one card and other one card systems.